I-High Purity oxygen generator abakhiqizi bejeneretha ye-oxygen

Isimiso Sokusebenza

Ama-molecule e-nitrogen anezinga lokusabalalisa ngokushesha kuma-micropores we-zeolite molecular sieve, futhi ama-molecule omoya-mpilo anezinga lokusabalalisa elihamba kancane.Ukusatshalaliswa kwamanzi ne-carbon dioxide emoyeni ocindezelwe kufana nalokho kwe-nitrogen.Ekugcineni, ama-molecule e-oksijini ayacetshiswa embhoshongweni we-adsorption.I-pressure swing adsorption ukukhiqizwa komoya-mpilo kusebenzisa izici ezikhethiwe zokukhangisa ze-zeolite molecular sieve, yamukela umjikelezo wokukhangisa okucindezelwe kanye ne-decompression desorption, futhi yenza umoya ocindezelwe ungene embhoshongweni we-adsorption ngokushintshana ukuze ubone ukuhlukaniswa komoya-mpilo ne-nitrogen, ukuze uqhubeke ukhiqiza okuphezulu. - ubumsulwa kanye ne-oxygen yekhwalithi ephezulu.

Ijeneretha ye-oxygen ye-PSA yamukela i-zeolite yekhwalithi ephezulu njenge-adsorbent ngokuya ngomgomo we-press swing adsorption.Ngaphansi kwengcindezi ethile, umoya-mpilo ukhishwa emoyeni, umoya ocindezelwe ohlanziwe futhi omisiwe, futhi i-adsorption ecindezelayo kanye ne-decompression desorption yenziwa ku-adsorber.Ngenxa yomphumela we-aerodynamic, izinga lokusatshalaliswa kwe-nitrogen kuma-micropores we-zeolite molecular sieve liphezulu kakhulu kunelomoya-mpilo.I-nitrogen ithandwa kakhulu ngesisefo se-molecular ye-zeolite, futhi umoya-mpilo uyacetshiswa esigabeni segesi ukuze kwakheke umoya-mpilo ophelile.Khona-ke, ngemva kokuwohloka kokucindezela komkhathi, isisefo semolekyuli sisusa initrogen ekhangisiwe nokunye ukungcola ukuze kubonakale ukuvuselelwa.Ngokuvamile, imibhoshongo emibili ye-adsorption isethwe ohlelweni, enye i-adsorption kanye nokukhiqizwa kwe-oxygen, kanti enye i-desorption nokuvuselela.Isilawuli sohlelo lwe-PLC silawula ukuvulwa nokuvalwa kwe-valve ye-pneumatic ukwenza imibhoshongo emibili ijikeleze ngokushintshana, ukuze kuzuzwe inhloso yokukhiqiza okuqhubekayo komoya-mpilo wekhwalithi ephezulu.

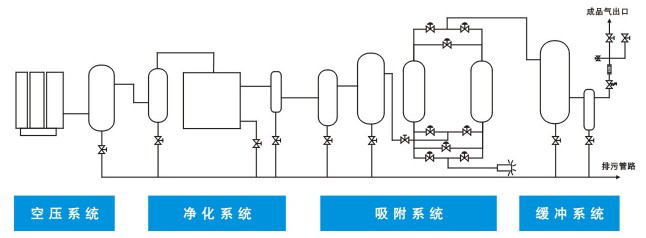

Ukugeleza kwesistimu

Uhlelo oluphelele lokukhiqiza umoya-mpilo luqukethe izingxenye ezilandelayo:

I-air compressor ➜ ithangi le-buffer ➜ idivayisi yokuhlanza umoya ecindezelwe ➜ ithangi lenqubo yomoya ➜ idivayisi yokuhlukanisa i-oxygen nitrogen ➜ ithangi le-oxygen process.

1. I-compressor yomoya

Njengomthombo womoya namandla wejeneretha ye-nitrogen, i-compressor yomoya ngokuvamile ikhethwa njengomshini wokukulufa kanye ne-centrifuge ukuze inikeze umoya ocindezelwe owanele wejeneretha ye-nitrogen ukuze kuqinisekiswe ukusebenza okuvamile kwejeneretha ye-nitrogen.

2. Ithangi le-buffer

Imisebenzi yethangi lokugcina yilena: ukubhafa, ukucindezela kokusimamisa nokupholisa;Ukuze kuncishiswe ukuguquguquka kwengcindezi yesistimu, susa ngokugcwele ukungcola kwamanzi kawoyela ngokusebenzisa i-valve ephansi ye-blowdown, wenze umoya ocindezelwe udlule kahle engxenyeni yokuhlanza umoya ocindezelweyo, futhi uqinisekise ukusebenza okuthembekile nokuzinzile kwemishini.

3. Idivayisi yokuhlanza umoya ecindezelwe

Umoya ocindezelwe osuka ethangini le-buffer uqala ukwethulwa emshinini wokuhlanza umoya ocindezelweyo.Iningi lamafutha, amanzi kanye nothuli kususwa isisetshenziswa sokususa amafutha esisebenza kahle kakhulu, bese siphinde sipholiswa ngesomisi esiqandisayo sokukhipha amanzi, ukukhishwa kukawoyela kanye nokukhishwa kothuli ngesisefo esihle, okulandelwa ukuhlanzwa okujulile.Ngokwezimo zokusebenza zesistimu, inkampani ye-hande iklame ngokukhethekile isethi yomshini wokukhipha umoya ocindezelwe ukuvimbela ukungena okungaba khona kukawoyela futhi inikeze ukuvikeleka okwanele kwesisefo samangqamuzana.Imodyuli eklanywe kahle yokuhlanza umoya iqinisekisa impilo yesevisi ye-zeolite molecular sieve.Umoya ohlanzekile ophathwa yile module ungasetshenziselwa igesi yensimbi.

4. Ithangi lenqubo yomoya

Umsebenzi wethangi lokugcina komoya ukunciphisa ukugobhoza komoya kanye ne-buffer;Ukuze kuncishiswe ukushintshashintsha kwengcindezi yesistimu nokwenza umoya ocindezelwe udlule ngokushelela kumhlangano wokuhlanza umoya ocindezelweyo, ukuze kususwe ngokugcwele ukungcola kwamanzi kawoyela futhi kuncishiswe umthwalo weyunithi yokuhlukaniswa kwe-PSA ye-oxygen ne-nitrogen elandelayo.Ngesikhathi esifanayo, ngesikhathi sokushintshwa komsebenzi wombhoshongo we-adsorption, iphinde inikeze i-PSA umoya-mpilo kanye neyunithi yokuhlukanisa i-nitrogen enenani elikhulu lomoya ocindezelwe odingekayo ekukhuphukeni kwengcindezi ngokushesha ngesikhathi esifushane, okwenza ingcindezi embhoshongweni we-adsorption ikhuphuke ingcindezi yokusebenza ngokushesha, iqinisekisa ukusebenza okuthembekile nokuzinzile kwemishini.

5. Iyunithi yokuhlukanisa i-oxygen nitrogen

Kunemibhoshongo emibili ye-adsorption a kanye no-B efakwe isisefo esikhethekile se-molecular generator ye-oxygen generator.Lapho umoya ocindezelwe ohlanzekile ungena ekugcineni kombhoshongo a futhi ugelezela ekugcineni kokuphuma ngesisefo samangqamuzana, i-nitrogen idonswa yiyo, futhi umoya-mpilo womkhiqizo ugeleza uphuma ekugcineni kombhoshongo we-adsorption.Ngemva kwesikhathi esithile, isisefo se-molecular tower a sigcwele.Ngalesi sikhathi, umbhoshongo umisa ngokuzenzakalelayo ukukhangiswa, umoya ocindezelwe ugeleza ungene ku-Tower B ukuze uthole ukumuncwa kwe-nitrogen nokukhiqizwa komoyampilo, bese uvuselela isisefo semolekyuli sombhoshongo a.Ukuvuselelwa kwesisefo samangqamuzana kubonakala ngokwehlisa ngokushesha umbhoshongo we-adsorption kungcindezi yomkhathi nokususa i-nitrogen ekhangisiwe.Le mibhoshongo emibili yenza i-adsorption kanye nokuvuselela ngokushintshana ukuze iqedele ukuhlukaniswa komoya-mpilo ne-nitrogen futhi ikhiphe umoya-mpilo ngokuqhubekayo.Izinqubo ezingenhla zilawulwa yi-programmable logic controller (PLC).Lapho ukuhlanzeka komoyampilo kusethiwe endaweni yokukhipha igesi, uhlelo lwe-PLC luzovula i-valve yokukhipha umoya othomathikhi ukuze ikhiphe ngokuzenzakalela umoya-mpilo ongafanelekile, inqamule umoya-mpilo ongafanelekile ukuthi ungagelezi uye endaweni esetshenziswa igesi, futhi isebenzise isithulisi ukunciphisa umsindo ongaphansi kuka-78dba. ngesikhathi sokukhipha igesi.

6. Ithangi lenqubo ye-oxygen

I-oxygen buffer tank isetshenziselwa ukulinganisa ingcindezi nokuhlanzeka komoyampilo okuhlukaniswe nesistimu yokuhlukanisa umoya-mpilo we-nitrogen ukuze kuqinisekiswe ukutholakala komoyampilo okuqhubekayo nokuzinzile.Ngasikhathi sinye, ngemuva kokushintshwa komsebenzi wombhoshongo we-adsorption, iphinda ishaje ingxenye yegesi yayo embhoshongweni we-adsorption, ongasizi nje kuphela ukuphakama kwengcindezi yombhoshongo we-adsorption, kodwa futhi idlala indima ekuvikeleni umbhede, futhi idlale. inqubo ebaluleke kakhulu indima asizayo inqubo yokusebenza imishini.

Imingcele Yezobuchwepheshe

Okukhipha umoya-mpilo: 5-300nm3 / h

Ukuhlanzeka komoyampilo: 90% - 93%

Umfutho we-oxygen: 0.3MPa

Indawo yamazolo: - 40 ℃ (ngaphansi kwengcindezi evamile)

Izici Zobuchwepheshe

1. Umoya ocindezelweyo ufakwe umshini wokuhlanza umoya nokomisa.Umoya ocindezelwe ohlanzekile futhi owomile usiza ekwandiseni impilo yesevisi yesisefo samangqamuzana.

2. I-valve yokumisa umoya omusha inesivinini sokuvula nokuvala ngokushesha, akukho ukuvuza nempilo ende yesevisi.Ingahlangabezana nokuvulwa kanye nokuvalwa kwenqubo ye-adsorption swing futhi inokwethenjelwa okuphezulu.

3. Ukugeleza kwedizayini yenqubo ephelele, ukusatshalaliswa komoya okufanayo, nokunciphisa umthelela wesivinini esikhulu sokugeleza komoya.Izingxenye zangaphakathi ezinokusetshenziswa kwamandla okunengqondo nezindleko zokutshala imali

4. Isisefo samangqamuzana esinamandla amakhulu, ukusebenza kahle okuphezulu kanye nokusetshenziswa kwamandla okuphansi kukhethiwe ukuze kulawulwe ngobuhlakani uhlelo lokuphefumula komoya-mpilo olungafanelekile ukuze kuqinisekiswe ikhwalithi ye-oxygen.

5. Izisetshenziswa zinokusebenza okuzinzile, ukusebenza okulula, ukusebenza okuzinzile, izinga eliphezulu lokuzenzakalela, ukusebenza okungahleliwe kanye nezinga eliphansi lokuhluleka lokusebenza konyaka.

6. Isebenzisa ukulawula kwe-PLC, okungakwazi ukubona ukusebenza okuzenzakalelayo okugcwele.Ingafakwa idivayisi ye-oxygen, ukugeleza, isistimu yokulawula okuzenzakalelayo kanye nesistimu yokulawula kude.

Inkambu yohlelo lokusebenza

1. Ukwenza insimbi ye-EAF: ukukhipha ikhabhoni, ukushisisa umoya-mpilo, ukuncibilika kwe-foam slag, ukulawulwa kwe-metallurgical kanye nokushisisa okuthunyelwe.

2. Ukwelashwa kwamanzi angcolile: i-oxygen enothisa i-aeration yodaka olucushiwe, i-pool oxygenation kanye nokuvalwa kwe-ozone.

3. Ukuncibilika kwengilazi: ukushiswa kwe-oxygen nokuhlakazeka, ukusika, ukwandisa ukuphuma kwengilazi nokwandisa impilo yesithando somlilo.

4. Ukwenziwa kwe-pulp bleaching kanye nokwenza iphepha: ukuxubha nge-chlorine kuguqulwa kube ukuxubha okunothiswe komoyampilo ukuze kuhlinzekwe nge-oxygen eshibhile nokwelashwa kwendle.

5. Ukuncibilikiswa kwensimbi okungeyona ayoni: Ukunothisa umoya-mpilo kuyadingeka ekuncibilikiseni insimbi, i-zinc, i-nickel nomthofu, futhi indlela ye-PSA kancane kancane ithatha indawo ye-cryogenic.

6. I-oksijeni yemboni ye-petrochemical kanye nemboni yamakhemikhali: ukucebisa komoya-mpilo kusetshenziselwa ukufaka esikhundleni somoya ukusabela kwe-oxidation ekuphenduleni komoya-mpilo embonini ye-petrochemical kanye nemboni yamakhemikhali, engathuthukisa isivinini sokusabela kanye nokuphuma kwemikhiqizo yamakhemikhali.

7. Ukucutshungulwa kwensimbi: esetshenziswa egolideni nakwezinye izinqubo zokukhiqiza ukuze kuthuthukiswe izinga lokukhishwa kwezinsimbi eziyigugu.

8. I-aquaculture: I-aeration enomoya-mpilo ingakhuphula umoya-mpilo oncibilikisiwe emanzini, ikhulise kakhulu ukukhiqizwa kwezinhlanzi, ihambise umoya-mpilo wezinhlanzi eziphilayo futhi ikhulise kakhulu izinhlanzi.

9. Ukuvutshelwa: Ukuvutshelwa komoyampilo kungena esikhundleni somoya ukuze unikeze umoya-mpilo wokuvutshelwa kwe-aerobic, okungathuthukisa kakhulu ukusebenza kahle kwamanzi okuphuza.

10. I-ozone: hlinzeka nge-oksijini kujeneretha ye-ozone ukuze uvale umoya-mpilo ngokwakho.

11. Isibhedlela: hlinzeka nge-oksijini yokuphefumula kombhede.Ukuhlanzeka, ukugeleza nokucindezela kuzinzile futhi kuyalungiseka ukuze kuhlangatshezwane nezidingo zamakhasimende ahlukene.